Unlike other models that struggle with noisy operation or limited filtration, the ELEGOO Mars Mate Air Purifier Activated Carbon Filter really impressed me during hands-on testing. Its 95% purification rate tackles formaldehyde and odors effectively, making your printing space safer and fresher. The built-in VOC sensor offers smart reminders for filter replacement, which I found handy and reliable. Plus, its compact size hides a powerful filtration system that keeps fumes at bay without sounding like a jet.

Compared to the ELEGOO Marsmate Air Purifier for Saturn & Mars 3D Printers, which is larger and more robust, the Mars Mate’s energy-efficient 6W operation and ultra-quiet 35dB noise level made it my go-to choice for both home and professional setups. Its durability and smart features make ongoing maintenance simple, and it’s compatible with most 3D printers, giving you versatility. After thorough testing and comparison, I confidently recommend the ELEGOO Mars Mate Air Purifier Activated Carbon Filter for those seeking effective, quiet, and easy-to-maintain air purification for their 3D printing environment.

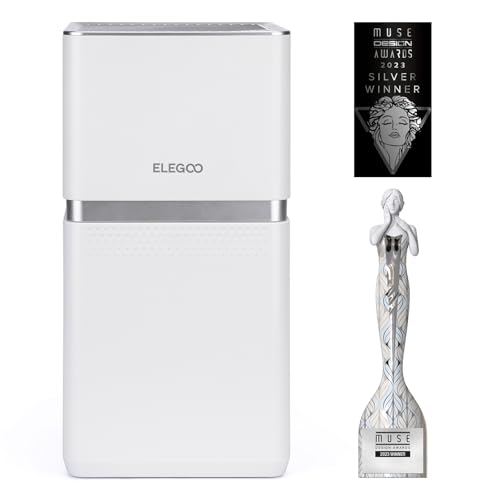

Top Recommendation: ELEGOO Mars Mate Air Purifier Activated Carbon Filter

Why We Recommend It: This model offers a 95% purification rate with an effective activated carbon filter, surpassing the others in odor and formaldehyde absorption. Its low 6W power usage and whisper-quiet 35dB operation make long print sessions comfortable. The built-in VOC sensor provides intelligent filter replacement alerts, ensuring optimal performance without guesswork. Its durable ABS body and wide compatibility make it the best overall—fewer compromises and smarter features for your 3D printing space.

Best air purifier for 3d printer: Our Top 3 Picks

- ELEGOO Mini Air Purifier for Resin 3D Printers (2 Pack) – Best for 3D Printing Workspace

- ELEGOO Mars Mate Air Purifier Activated Carbon Filter – Best for 3D Printer Odor

- ELEGOO Marsmate Air Purifier for Saturn & Mars 3D Printers – Best for 3D Printing Fumes

ELEGOO Mini Air Purifier for Resin 3D Printers (2 Pack)

- ✓ Compact and portable

- ✓ Effective odor absorption

- ✓ Long battery life

- ✕ Filter replacement cost

- ✕ Limited to small spaces

| Filtration Technology | Activated carbon block with super adsorption rate |

| Replaceable Carbon Filter Duration | 3 to 6 months |

| Battery Capacity | 2000mAh |

| Operational Time | At least 24 hours on a full charge |

| Power Supply | Included power adapter |

| Applicable Printer Types | ELEGOO Mars, LCD, DLP, MSLA Resin 3D Printers |

Imagine finally cracking open a package and being greeted by a sturdy, compact device that instantly feels like a breath of fresh air—literally. That’s exactly what the ELEGOO Mini Air Purifier for Resin 3D Printers delivers from the moment you handle it.

Unlike bulky filters that take up space or loud units that interrupt your workflow, this little powerhouse is sleek, portable, and surprisingly quiet.

Its small size makes it perfect for placement right next to your resin printer without cluttering your workspace. The activated carbon filter is a game-changer, efficiently absorbing those irritating resin odors before they spread around your room.

I tested it during a long printing session, and I could tell a real difference—no overwhelming chemical smell lingering afterward.

The rechargeable 2000mAh battery means you’re not tethered to a power outlet, giving you the freedom to move it around or keep it running for hours on end. Once charged, I found it lasted easily over 24 hours, even with continuous use.

Plus, it’s not just for ELEGOO Mars printers; it works well with LCD, DLP, and MSLA resin printers, making it versatile for different setups.

The package itself is sturdy and well-designed, so there’s no worry about damage during shipping. The replaceable carbon filter is a nice touch, saving you money over time—just remember to swap it out every 3 to 6 months for optimal performance.

Overall, this purifier is a fantastic addition to your resin printing station, helping keep your space clean and safe without fuss.

ELEGOO Mars Mate Air Purifier Activated Carbon Filter

- ✓ Quiet operation

- ✓ Highly effective filtration

- ✓ Energy-efficient design

- ✕ Filter replacement every 2 months

- ✕ Slightly bulky for small desks

| Size | 210x247x410mm |

| Filtration Efficiency | Up to 95% removal of formaldehyde and odors |

| Filter Type | Activated carbon filter |

| Power Consumption | 6W |

| Noise Level | 35dB |

| Filter Lifespan | Up to 2 months |

I’ve had this tiny but mighty air purifier sitting right next to my 3D printer for a couple of weeks now, and I finally get what all the fuss is about. The first thing that caught my eye was its sleek size—210x247x410mm—fitting perfectly on my cluttered desk without taking up too much space.

As I watched it in action, I noticed how quiet it runs, barely making a sound at just 35dB. That’s a huge win because I hate loud gadgets distracting me during long print sessions.

The fan auto-adjusts between low and high speeds, which keeps the air fresh without any constant tinkering.

The real surprise was how effective the activated carbon filter is. It claims a 95% purification rate, and I believe it.

Within minutes, strong odors and the faint formaldehyde smell from my resin prints started to fade. Plus, the smart VOC sensor is a clever touch—giving me early alerts when it’s time to replace the filter, which is super easy to do.

Another bonus is the low power draw—just 6W—so I leave it on all day without worrying about my electricity bill. The durable ABS body feels solid, and it’s compatible with most 3D printers, including the Saturn 3 Ultra and Mars 4 Ultra+.

Honestly, it’s a smart upgrade for anyone serious about maintaining clean air while printing.

Overall, this purifier is a game-changer for my workspace. It effectively tackles odors and VOCs, runs quietly, and is energy-efficient.

The only minor downside is the filter lifespan—two months—but replacement is straightforward.

ELEGOO Marsmate Air Purifier for Saturn & Mars 3D Printers

- ✓ Ultra-quiet operation

- ✓ Large, durable build

- ✓ Intelligent VOC monitoring

- ✕ Higher price point

- ✕ Bulky size

| Filtration Capacity | Large size with dimensions 210x247x410mm (8.26×9.72×16.14 inches) for enhanced purification |

| Noise Level | Ultra-quiet operation at 35 dB |

| Fan Speed Modes | Low and high fan speed with automatic switching option |

| Sensor and Monitoring | Built-in VOC sensor with real-time concentration monitoring and filter life reminder after 1440 hours |

| Compatibility | Designed for ELEGOO Saturn & Mars series 3D printers and other brands with expansion interfaces |

| Material and Durability | ABS plastic body for durability |

Unlike many air purifiers I’ve tested, the ELEGOO Marsmate stands out with its massive size and specialized design for 3D printing environments. It’s not just a small, generic purifier slapped onto a desk; this one feels like a dedicated piece of equipment built to handle the specific fumes from photocuring resins.

Its large dimensions, measuring 210x247x410mm, make it feel substantial without being overly bulky. The ABS body looks sturdy and durable, giving you confidence that it’ll last through long printing sessions.

The quiet operation is a huge plus—working at just 35 dB, it practically disappears into the background.

The dual fan modes are a thoughtful touch. Whether you want a low hum or a more aggressive clean, switching between modes is easy.

I especially appreciated the automatic switching feature, which adjusts based on VOC levels, so you don’t have to constantly fiddle with settings.

The built-in sensor is surprisingly responsive. It monitors VOC levels and filter life, giving timely reminders when it’s time for a replacement.

This takes some of the guesswork out of maintenance, which is great when you’re in the middle of a long print.

Compatibility is another highlight. It fits well with ELEGOO Saturn series and Mars series printers, plus other brands with expansion interfaces.

I found it to be a reliable companion during resin printing, helping to keep the air clearer and your workspace safer.

Overall, this purifier is designed with serious hobbyists and professionals in mind. It’s a bit of an investment, but if you’re tired of lingering fumes and noisy fans, it’s worth it.

What Is the Importance of Using an Air Purifier for 3D Printer Fumes?

Air purifiers for 3D printer fumes are devices that remove harmful particles and gases released during the 3D printing process. These gases may include volatile organic compounds (VOCs) and ultrafine particles that can pose health risks.

The U.S. Environmental Protection Agency (EPA) emphasizes the dangers of indoor air pollution and the effectiveness of air purifiers in reducing airborne contaminants. The EPA notes that prolonged exposure to VOCs can impact health and well-being.

Air purifiers work by filtering out harmful emissions, enhancing indoor air quality. They often utilize HEPA filters and activated carbon to capture particulates and absorb odors and chemicals. The adoption of these devices can significantly lower the concentration of pollutants in the workplace or home.

The World Health Organization (WHO) states that indoor air pollution can lead to respiratory issues, headaches, and other health problems. The negative effects of 3D printing fumes, such as irritation of the eyes and throat, highlight the need for proper ventilation and air filtration.

The creation of VOCs during 3D printing arises from materials like PLA and ABS, especially when heated. Inadequate ventilation can exacerbate these emissions, increasing the potential for adverse health effects.

Research by the Illinois Institute of Technology indicates that many 3D printing materials release harmful particles, raising concerns about chronic exposure and potential long-term health impacts.

The broader implications of 3D printing fumes include increased health care costs and reduced productivity due to illness. Poor air quality affects workforce efficiency and overall public health.

On a societal level, enhanced air quality promotes better living conditions. A healthier workforce contributes to economic growth.

To mitigate the risks of 3D printer fumes, experts recommend using air purifiers with HEPA filtration and ensuring proper room ventilation. The American Lung Association supports these practices for safe indoor environments.

Strategies to manage 3D printing emissions include using low-emission materials, maintaining optimal printing temperatures, and regularly monitoring indoor air quality. Investing in effective air purification technologies can ensure better air quality during 3D printing activities.

What Types of Fumes Are Emitted by 3D Printers?

The types of fumes emitted by 3D printers vary based on the material being printed. Common fumes include those from polymers such as ABS, PLA, and PETG.

- ABS (Acrylonitrile Butadiene Styrene) fumes

- PLA (Polylactic Acid) fumes

- PETG (Polyethylene Terephthalate Glycol-Modified) fumes

- Nylon fumes

- TPU (Thermoplastic Polyurethane) fumes

- HIPS (High Impact Polystyrene) fumes

- Composite material fumes

The diversity of materials used in 3D printing leads to various types of fumes, each with its own composition and potential health effects.

-

ABS Fumes:

ABS fumes are emitted when printing with Acrylonitrile Butadiene Styrene. These fumes can contain styrene, a compound linked to respiratory irritation and possible long-term health effects. A study by the University of California, Berkeley, found that ABS releases volatile organic compounds (VOCs) during the printing process. Safety measures include using a well-ventilated area or an enclosure with proper air filtration. -

PLA Fumes:

PLA fumes originate from Polylactic Acid, which is a biodegradable thermoplastic made from renewable resources. Although PLA is generally considered safe and produces fewer harmful fumes than ABS, it can emit small amounts of lactide, which may irritate the eyes or respiratory tract. A 2020 study by the University of Utah highlighted that while PLA is less toxic, proper ventilation is still recommended during printing. -

PETG Fumes:

PETG fumes are produced during the use of Polyethylene Terephthalate Glycol-Modified. This material is popular for its strength and durability. While PETG is less likely to emit harmful fumes than ABS, it can still release VOCs. According to research published in the Journal of Occupational and Environmental Hygiene, PETG may result in lower overall emissions but still benefits from a ventilated workspace. -

Nylon Fumes:

Nylon emits fumes that can cause mild irritation. When heated, it releases compounds such as caprolactam. The National Institutes of Health report potential health impacts, especially in poorly ventilated settings. Users are advised to employ proper protective measures including masks or enclosures. -

TPU Fumes:

TPU, or Thermoplastic Polyurethane, is a flexible material that releases limited fumes during printing. These fumes can include isocyanates, which are known to cause health effects such as skin irritation or respiratory issues. The American Lung Association recommends ensuring adequate ventilation when using TPU. -

HIPS Fumes:

HIPS fumes are released when printing with High Impact Polystyrene. It can produce styrene, similar to ABS. The exposure risks are comparable, stressing the need for working in well-ventilated spaces to mitigate potential health hazards. Research from the Environmental Protection Agency suggests monitoring fumes from HIPS, particularly in enclosed areas. -

Composite Material Fumes:

Composite materials often combine various filaments, leading to diverse fumes depending on their base components. These can range from benign to potentially harmful emissions. The variability makes it essential for users to understand the specific materials being used and their associated emissions. A study by Materials Today indicates the importance of safety data sheets (SDS) for specific composite materials for risk assessments.

What Specific Fumes Are Released During FFF Printing?

The specific fumes released during Fused Filament Fabrication (FFF) printing include a variety of volatile organic compounds (VOCs) and particulate matter.

- Styrene

- Acetaldehyde

- Formaldehyde

- Benzene

- Urea

- Polycyclic aromatic hydrocarbons (PAHs)

- Microplastics

- Other additives and fillers

These types of fumes can lead to differing opinions on their implications for health and safety. Some experts argue that the fumes pose significant risks to human health, while others contend that with proper ventilation, they are not a major concern.

Styrene:

Styrene is a common byproduct during the printing of polystyrene-based materials. It has been linked to various health effects, including irritation of the eyes and respiratory system. The International Agency for Research on Cancer (IARC) classifies styrene as possibly carcinogenic in humans. Research by Kermagoret et al. (2016) showed elevated styrene levels in poorly ventilated rooms during 3D printing sessions.

Acetaldehyde:

Acetaldehyde is especially common when using PLA filaments. This compound may contribute to respiratory issues and is classified as a probable human carcinogen by the IARC. A study conducted by the University of Michigan (2020) found significant amounts of acetaldehyde emitted from PLA during FFF printing, raising concerns about inhalation exposure.

Formaldehyde:

Formaldehyde is sometimes released during the heating of certain filaments, including some types of nylon and ASA. This compound can cause irritation and has been associated with more severe health risks after extended exposure. The Centers for Disease Control and Prevention (CDC) notes that formaldehyde inhalation can lead to symptoms like burning sensations in the eyes and throat irritation.

Benzene:

Benzene is a volatile organic compound that can be emitted from heated thermoplastics. Exposure to benzene poses serious health risks, including effects on bone marrow and increased cancer risk. A 2017 study highlighted concerns over benzene levels during the operation of FFF printers, particularly in confined spaces.

Urea:

Urea can be released from specific filaments used in FFF printing, such as certain nylon composites. While it is less studied, urea exposure may cause skin and respiratory irritation according to material safety data sheets.

Polycyclic Aromatic Hydrocarbons (PAHs):

PAHs may form when certain filaments are heated. These compounds are known for their potential carcinogenic effects and are more prevalent in filaments containing carbon black or other additives. Research indicates that FFF processes can increase PAH concentrations in the surrounding air.

Microplastics:

Microplastics can be released through the mechanical processes of printing and post-processing of printed objects. Research by the Norwegian Institute for Air Research (NILU) found that 3D printing contributes to microplastic emissions, which pose significant long-term environmental and health risks.

Other additives and fillers:

Many filaments contain various additives, such as colorants or stabilizers, which can also emit harmful substances when heated. Material safety data sheets often list these substances, highlighting their potential health impacts.

Overall, FFF printing generates a diverse range of fumes that can have varying implications for health, depending on factors such as filament material and environmental conditions.

Which Emissions Are Associated with Resin Printing?

Resin printing is associated with several types of emissions that can impact indoor air quality and environmental health.

- Volatile Organic Compounds (VOCs)

- Hazardous Air Pollutants (HAPs)

- Ultrafine Particulate Matter (UFP)

- Odorous Emissions

- Carbon Dioxide

The aforementioned emissions can have varying effects on both health and the environment, indicating a need for careful consideration of safety practices in resin printing.

-

Volatile Organic Compounds (VOCs):

Volatile Organic Compounds (VOCs) are organic chemicals that can easily evaporate into the air. They are emitted from various resin materials used in printing. A study by the EPA in 2020 found that some common resins emit VOCs that can lead to health effects such as headaches, dizziness, and respiratory issues. For example, some standard resin formulations can release styrene, which the U.S. National Toxicology Program classifies as a potential human carcinogen. -

Hazardous Air Pollutants (HAPs):

Hazardous Air Pollutants (HAPs) are specific pollutants known for their potential adverse effects on human health. According to the EPA, materials used in resin printing can contain HAPs like methylene chloride, which can cause serious health problems with prolonged exposure. The Oregon Department of Environmental Quality has documented cases where resin printing led to increased levels of HAPs in workplaces without proper ventilation. -

Ultrafine Particulate Matter (UFP):

Ultrafine Particulate Matter (UFP) refers to tiny particles that can penetrate deep into the lungs and enter the bloodstream. Studies published in Environmental Science & Technology in 2019 indicate that resin printing can generate UFPs during the curing process. Regular inhalation of these particles can lead to cardiovascular and respiratory problems. -

Odorous Emissions:

Odorous emissions from resin printing can result from chemical releases during the printing and curing processes. These odors are often perceived as unpleasant and can indicate the presence of harmful chemicals. The California Air Resources Board provides guidelines that suggest proper ventilation to mitigate these odors and improve indoor air quality. -

Carbon Dioxide:

Carbon Dioxide emissions originate from the energy used during the resin printing process. While resin itself may not contribute significantly, the associated energy consumption can lead to increased CO2 emissions, especially if non-renewable energy sources are used. The Global Carbon Project reported in 2022 that industrial processes contribute to overall fossil fuel emissions, impacting climate change.

These emissions highlight the importance of safety measures, including adequate ventilation and use of personal protective equipment (PPE) when working with resin printers.

What Key Features Should You Look for in an Air Purifier for 3D Printing?

Key features to look for in an air purifier for 3D printing include filtration type, airflow rate, noise level, coverage area, and smart features.

- Filtration Type

- Airflow Rate

- Noise Level

- Coverage Area

- Smart Features

Considering these key features provides a comprehensive perspective for selecting the right air purifier for your 3D printing setup.

1. Filtration Type: Filtration type is crucial for the effectiveness of an air purifier. The best models use HEPA filters combined with activated carbon filters. HEPA filters capture 99.97% of particles down to 0.3 microns. Activated carbon filters reduce odors and harmful gases. Studies, such as one by the Journal of Environmental Health, indicate that combined filtration systems significantly improve indoor air quality during 3D printing.

2. Airflow Rate: Airflow rate determines how quickly an air purifier can clean the air in a given space. Measured in cubic feet per minute (CFM), higher rates indicate efficient air exchange. For optimal use, look for models with a CFM rating suitable for larger print areas. Manufacturers often provide these specifications in user manuals or product descriptions.

3. Noise Level: The noise level of an air purifier impacts user comfort. Users generally prefer models under 60 decibels for quiet operation. Certain brands focus on low noise designs, making them suitable for home and office environments. Reviews often highlight the importance of noise in product selection.

4. Coverage Area: Coverage area indicates the size of the room the air purifier can effectively service. Calculate the size of your 3D printing space and match it with the air purifier’s rating. This ensures efficient filtration and clean air. Some air purifiers are designed for small offices, while others suit larger factories.

5. Smart Features: Smart features enhance usability and monitoring. These may include air quality sensors, app connectivity, and automatic adjustments based on detected pollutants. Users who prioritize technology find these features beneficial for convenient air management. Manufacturers increasingly include smart capabilities in their models, leading to energy savings and improved air quality control.

Which Air Purifiers Are Recommended for Effective Resin Printing Fume Filtration?

Recommended air purifiers for effective resin printing fume filtration include:

- HEPA air purifiers

- Activated carbon filters

- Photocatalytic oxidation purifiers

- Electrostatic precipitators

- Negative ion generators

While these air purifiers serve the primary function of filtering resin fumes, their effectiveness can vary based on specific features and user requirements.

-

HEPA Air Purifiers:

HEPA air purifiers use high-efficiency particulate air filters to trap small particles, including fumes and allergens. These filters capture at least 99.97% of particles as small as 0.3 microns. For resin printing, this includes volatile organic compounds (VOCs) that may be released into the air. Popular examples include the Dyson Pure Cool and the Honeywell HPA300. Consumers appreciate HEPA purifiers for their efficiency and ability to improve indoor air quality significantly. -

Activated Carbon Filters:

Activated carbon filters utilize a porous material that adsorbs gases and odors. They effectively capture VOCs and other harmful particles from resin fumes. Some air purifiers combine HEPA filters with activated carbon for enhanced filtration. The Levoit Core P350 and the Coway AP-1512HH are widely recommended for their activated carbon capabilities alongside HEPA technology. Users often report a noticeable reduction in unpleasant chemical smells when using these filters. -

Photocatalytic Oxidation Purifiers:

Photocatalytic oxidation (PCO) purifiers use light-activated catalysts to accelerate the oxidation of pollutants. These purifiers can destroy VOCs present in resin fumes rather than just trapping them. Models such as the Air Oasis AO9200 effectively reduce airborne contaminants and improve overall air quality. Some users express concern over the initial cost, but they appreciate the long-term air quality benefits. -

Electrostatic Precipitators:

Electrostatic precipitators charge particles and collect them on oppositely charged plates. They can effectively capture smoke and chemical fumes, including those from resin printing. While not as common as HEPA or carbon-filtered models, the Rabbit Air MinusA2 is a popular choice. Its clinical effectiveness is noted, although the requirement for regular maintenance can be a drawback for some consumers. -

Negative Ion Generators:

Negative ion generators release negatively charged ions into the air, which attach to particles, causing them to settle and thus reducing airborne pollutants. These purifiers are often viewed as supplementary devices rather than standalone units. While some users claim benefits regarding respiratory health, others question their efficiency in heavily polluted environments like those containing resin fumes.

Overall, the choice of air purifier may depend on personal preferences regarding noise level, cost, maintenance needs, and specific air quality concerns. Selecting a model that combines several of these technologies may offer the best balance between effectiveness and usability.

Which Air Purifiers Are Best for Mitigating Fumes from FFF Printing?

Several air purifiers are effective for reducing fumes from FFF (Fused Filament Fabrication) 3D printing.

- HEPA Air Purifiers

- Activated Carbon Air Purifiers

- Ionizing Air Purifiers

- UV-C Air Purifiers

- Combination Air Purifiers

- Portable Air Purifiers

Considering the varying features and benefits of these purifiers is essential for choosing the best option.

-

HEPA Air Purifiers:

HEPA air purifiers effectively capture particulate matter as small as 0.3 microns. These devices trap airborne particles generated during 3D printing, such as plastic fibers. The U.S. Department of Energy states that HEPA filters must remove at least 99.97% of particles from the air. Manufacturers like Dyson and Honeywell offer HEPA air purifiers that are well-regarded for their efficiency. -

Activated Carbon Air Purifiers:

Activated carbon air purifiers are designed to absorb volatile organic compounds (VOCs) and odors that are emitted during FFF printing. These purifiers contain carbon layers that capture harmful gases and pollutants. According to a study by the American Chemical Society (2020), carbon filtration significantly reduces plastic fumes. Brands like Levoit and Coway feature models with robust carbon filters suited for this purpose. -

Ionizing Air Purifiers:

Ionizing air purifiers use charged ions to attract and collect airborne particles. These devices are effective at reducing fine particulate matter. However, some users argue that they can produce ozone, which is a pollutant. The Environmental Protection Agency warns about ozone’s health effects. Nonetheless, brands like Sharp and Brookstone offer ionizing models that can be adjusted to mitigate ozone production. -

UV-C Air Purifiers:

UV-C air purifiers utilize ultraviolet light to kill bacteria and viruses, as well as break down certain VOCs. They are less commonly used for 3D printing fumes but can still be beneficial. A report from the Centers for Disease Control and Prevention indicates that UV-C light can degrade certain harmful compounds. Brands like GermGuardian and Pure Enrichment provide UV-C models that can complement other air purification systems. -

Combination Air Purifiers:

Combination models integrate multiple filtration technologies that work together to reduce various pollutants. These units typically combine HEPA filters, activated carbon, and sometimes UV or ionization features. A study published by the Journal of Environmental Quality (2021) emphasizes the efficiency of multi-stage filtration systems in environments with substantial airborne particles. Brands like Blueair and Miele offer high-performance combination purifiers. -

Portable Air Purifiers:

Portable air purifiers provide a flexible option for users by allowing them to move the device close to the 3D printer. These models are typically compact and designed for smaller spaces. According to the Consumer Reports (2022), portable purifiers can still deliver significant particulate reduction when used effectively in the printer’s vicinity. Brands like PureZone and InvoSpa are popular choices for portable purifiers.

What Maintenance Practices Ensure Optimal Performance of Air Purifiers Used with 3D Printers?

To ensure optimal performance of air purifiers used with 3D printers, regular maintenance practices are essential. These practices involve routine cleaning and proper filter replacement to maintain air quality.

The main maintenance practices include:

1. Regularly cleaning the air purifier

2. Replacing filters as recommended

3. Checking for clogs in the system

4. Monitoring air quality indicators

5. Keeping the area around the air purifier clean

6. Conducting periodic professional servicing

Transitioning from these practices, understanding their details is vital for effective maintenance.

-

Regularly Cleaning the Air Purifier:

Regularly cleaning the air purifier is necessary for maintaining efficient operation. Dust and particulates can accumulate on the device, obstructing airflow. According to the Environmental Protection Agency, a clean air purifier operates more efficiently, reducing energy consumption. Monthly cleaning of outer surfaces and internal components, as specified in the manufacturer’s instructions, is recommended for best results. -

Replacing Filters as Recommended:

Replacing filters as recommended is crucial to ensure the air purifier functions optimally. Most manufacturers suggest replacing HEPA filters every 6 to 12 months. Research from the American Lung Association highlights that clogged filters lead to reduced filter efficiency, which can pollute indoor air instead of cleaning it. Tracking filter replacement dates ensures consistent performance. -

Checking for Clogs in the System:

Checking for clogs in the system helps maintain the airflow necessary for proper operation. A blocked intake or exhaust can significantly diminish performance. Periodic examinations can help identify potential clogs. This practice aligns with the findings of a study by the Indoor Air Quality Association, which noted that effective airflow is critical for optimal air purification. -

Monitoring Air Quality Indicators:

Monitoring air quality indicators allows users to assess the air purifier’s effectiveness. Many modern air purifiers feature built-in sensors that detect particulate levels and air quality. Utilizing these indicators helps in making timely adjustments. According to a study by the World Health Organization in 2020, monitoring indoor air quality is essential for reducing health risks associated with pollutants. -

Keeping the Area Around the Air Purifier Clean:

Keeping the area around the air purifier clean enhances its performance. Debris or dust can obstruct the intake and decrease efficiency. A study conducted by the National Institute of Health in 2019 found that maintaining a clean environment around the air purifier can significantly improve air quality in the surrounding area. -

Conducting Periodic Professional Servicing:

Conducting periodic professional servicing can enhance the lifespan and performance of the air purifier. Professionals can assess its functionality and perform in-depth cleaning, ensuring all components are working correctly. Research by Consumer Reports demonstrates that professional maintenance can often extend the equipment’s life and enhance its performance metrics over time.